Tungsten-copper Electrode for Electric Spark

- Categories:Tungsten-molybdenum Electrode

- Author:

- Origin:

- Time of issue:2017-11-21 00:00

- Views:

(Summary description)Tungsten-copper alloy electrodes are formed by combining high-purity tungsten powder with high-purity high-plasticity high-conductivity copper powder and then carrying out static pressure molding and high-temperature sintering.

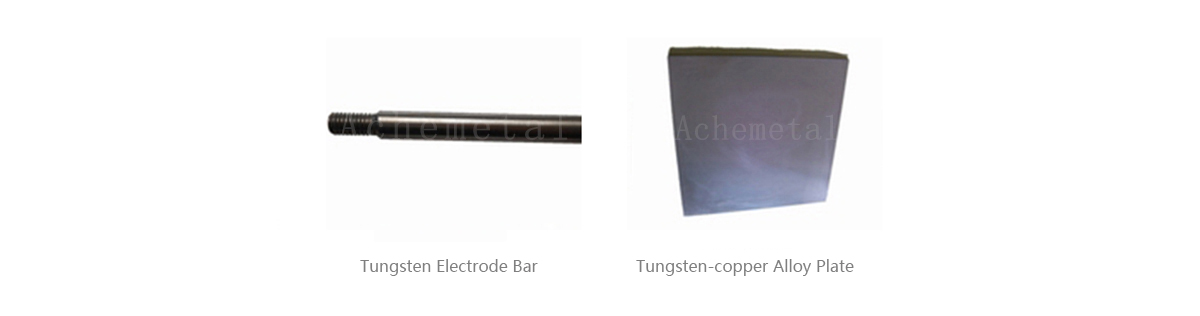

Tungsten-copper Electrode for Electric Spark

(Summary description)Tungsten-copper alloy electrodes are formed by combining high-purity tungsten powder with high-purity high-plasticity high-conductivity copper powder and then carrying out static pressure molding and high-temperature sintering.

- Categories:Tungsten-molybdenum Electrode

- Author:

- Origin:

- Time of issue:2017-11-21 00:00

- Views:

Business Consulting:+86-13526941255 Yanyan

Business Consulting:+86-13526941255 Yanyan

Email:yanyan@achemetal.net

Tungsten-copper alloy electrodes are formed by combining high-purity tungsten powder with high-purity high-plasticity high-conductivity copper powder and then carrying out static pressure molding and high-temperature sintering. As electric spark molding electrodes, they have the following advantages:

1. High hardness, low consumption, reduction in electrode length;

2. High electric conductivity, high processing speed;

3. High hardness and high electric conductivity: tungsten-carbon steel materials of which common copper cannot discharge electricity can be smoothly machined;

4. High tensile strength: it is suitable for processing products in complicated shapes;

5. The integrity of copper workpieces can be kept even in long-term discharge, so the molds are high in precision;

6. Uniform texture, small contact surface losses;

7. High stability during high-speed operation;

Our company can manufacture specially-shaped tungsten-copper materials of various dimensions according to the requirements of customers. The copper content of electrodes can be adjusted between 15% and 45% according to the requirements of customers.

+8613526941255

+8613526941255

Message

Message