Crucible

- Categories:High-temperature Vacuum Furnace

- Author:

- Origin:

- Time of issue:2017-11-21 00:00

- Views:

(Summary description)Tungsten powder or molybdenum powder is directly subjected to sintering molding or hot isostatic pressing molding, and is mostly used for manufacturing large crucibles of sintering furnaces, crystal growth furnaces, glass smelting and rear earth smelting equipment. Particularly, these kinds of crucibles are used in furnaces of growing sapphire crystals by KY method, EFG method and heat exchange method in large quantity. Usually, the wall thickness is 8-15mm; the diameter is 100-600mm; the height is 50-700mm. The purity of these kinds of crucibles: W≥99.95%; the density usually can reach 18.2g/cm3; and the density can reach more than 18.8g/cm3 by a hot isostatic pressing technology as required specially. The density of molybdenum crucibles usually can reach about 10.0g/cm³.

Crucible

(Summary description)Tungsten powder or molybdenum powder is directly subjected to sintering molding or hot isostatic pressing molding, and is mostly used for manufacturing large crucibles of sintering furnaces, crystal growth furnaces, glass smelting and rear earth smelting equipment. Particularly, these kinds of crucibles are used in furnaces of growing sapphire crystals by KY method, EFG method and heat exchange method in large quantity. Usually, the wall thickness is 8-15mm; the diameter is 100-600mm; the height is 50-700mm. The purity of these kinds of crucibles: W≥99.95%; the density usually can reach 18.2g/cm3; and the density can reach more than 18.8g/cm3 by a hot isostatic pressing technology as required specially. The density of molybdenum crucibles usually can reach about 10.0g/cm³.

- Categories:High-temperature Vacuum Furnace

- Author:

- Origin:

- Time of issue:2017-11-21 00:00

- Views:

Business Consulting:+86-13526941255 Yanyan

Email:yanyan@achemetal.net

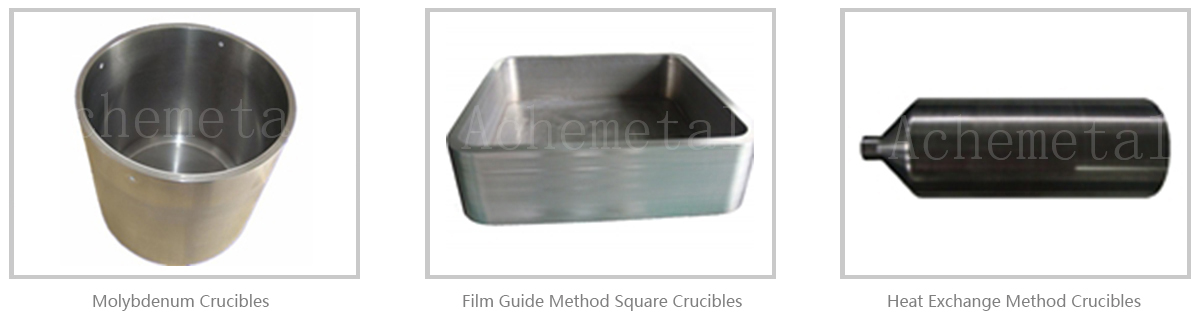

Large Sintered Crucible

Tungsten powder or molybdenum powder is directly subjected to sintering molding or hot isostatic pressing molding, and is mostly used for manufacturing large crucibles of sintering furnaces, crystal growth furnaces, glass smelting and rear earth smelting equipment. Particularly, these kinds of crucibles are used in furnaces of growing sapphire crystals by KY method, EFG method and heat exchange method in large quantity. Usually, the wall thickness is 8-15mm; the diameter is 100-600mm; the height is 50-700mm. The purity of these kinds of crucibles: W≥99.95%; the density usually can reach 18.2g/cm3; and the density can reach more than 18.8g/cm3 by a hot isostatic pressing technology as required specially. The density of molybdenum crucibles usually can reach about 10.0g/cm³.

At present, Achemetal has had the capacity of producing ultra-large crucibles of which the diameter and height are more than 1m.

Sintered tungsten crucibles and molybdenum crucibles for sapphire crystal growing furnaces of various types.

Vacuum Coating Crucibles

The crucibles are formed by turning formation of tungsten bars and molybdenum bars after forging or hot isostatic pressing, generally with smaller dimensions and higher density. Usually, the wall thickness is 3-10mm; the diameter is less than 80mm. They are mostly used for sintering furnaces or vacuum evaporation coating machines of small ceramics and other materials. The purity of these crucibles: W≥99.95%; according to different diameters, the density of tungsten crucibles usually can reach 18.5 to 19g/cm3; the density of molybdenum crucibles is about 10.0g/cm3.

Spinning Crucible

Crucibles formed by processing tungsten plates or molybdenum plates by a rotary pressing technology feature high strength, low cost and small thermal inertia, and have been accepted by more and more customers.

Rotary Pressing Crucible for Hem Crystal Growing Furnace

Currently, Achemetal can produce 15-in, 18-in and 20-in spinning crucible crucibles and crucible covers in series. With the progress of crystal growing technologies, we can provide larger products at any time. Spinning crucible crucibles produced by Achemetal are high in purity and creep resistance.

Welded Crucible

Welded Molybdenum Crucible

If crucibles are manufactured by a welding method, the cost can be reduced. However, tungsten and molybdenum have relatively low welding properties. Currently, crucibles are limited in the range of smaller wall thickness and low requirements on the air tightness of crucibles.

Welded Crucible for Sapphire Crystal Furnace

In equipment for producing sapphire crystals by a Bridgman-Stockbarger (BS) method, welded molybdenum crucibles are used in large quantity. Currently, Achemetal can produce 2-in, 4-in and 6-in welded molybdenum crucibles. With the development of crystal growing demands, Achemetal can manufacture larger molybdenum welded crucibles.

+8613526941255

+8613526941255

Message

Message