Tungsten-copper

Tungsten copper material is an alloy of tungsten and copper, which has integrated the advantages of tungsten and copper, features high-temperature resistance, arc erosion resistance, high strength, large specific gravity, electric conduction, good heat conduction, easy cutting and transpiration cooling properties, and can be widely applied to machinery, power, electronics, metallurgy, aerospace and other industries when used as vacuum contact materials, electrode materials, electronic packaging materials as well as materials for rockets, guided missiles and other special purposes.

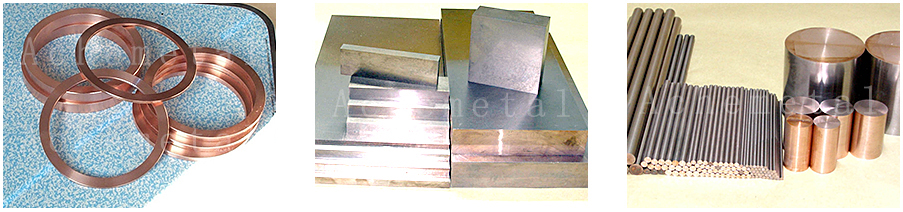

Due to the adoption of isostatic press molding - high-temperature sintering tungsten framework - copperizing process, our company can produce various large specially-shaped parts with the copper content of 6-90%. Our products feature high purity, uniform texture and excellent properties. Due to the adoption of compression molding, extrusion molding and injection molding, we can produce various sheets, rods, pipes, plates and small products in complicated s shapes.

Main indexes of tungsten-copper material

| Grade | Density g/cm³ | Electric conductivity %IACS | HB MPa | Dimensions mm |

| WCu50 | 11.9~12.3 | ≥55 | 1130~1180 | Tube: Ø3~390 Length<500 Sheet: Width<390 Length<500 Special type: Width<390 Length<500 |

| WCu40 | 12.8~13.0 | ≥47 | ≥1375 | |

| WCu30 | 13.8~14.4 | ≥42 | ≥1720 | |

| WCu20 | 15.2~15.6 | ≥34 | ≥2160 | |

| WCu10 | 16.8~17.2 | ≥27 | ≥2550 | |

| WCu7 | 17.3~17.8 | ≥26 | ≥2900 |

Properties of W-Cu electronic packaging materials with different components

| Material components(wt%) | W-10Cu | W-15Cu | W-20Cu | W-25Cu | W-30Cu |

| Specific gravity(g/cm³) | 17.1 | 16.4 | 15.5 | 14.8 | 14.2 |

| Thermal conductivity(W/m·K) | 191 | 198 | 221 | 235 | 247 |

| Thermal expansion coefficient (×10-6/K) | 6.3 | 7.1 | 7.6 | 8.5 | 9.0 |

Main application

▲High-performance materials for aerospace

▲Vacuum contact materials

+8613526941255

+8613526941255

Message

Message