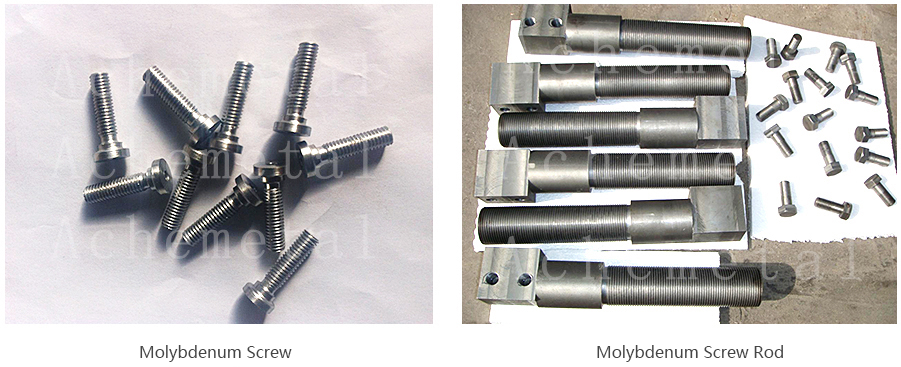

Molybdenum Screws, Molybdenum Nuts and Other Fasteners

Fasteners include screws, nuts, pins, rivets, gaskets, spacing pieces, etc.

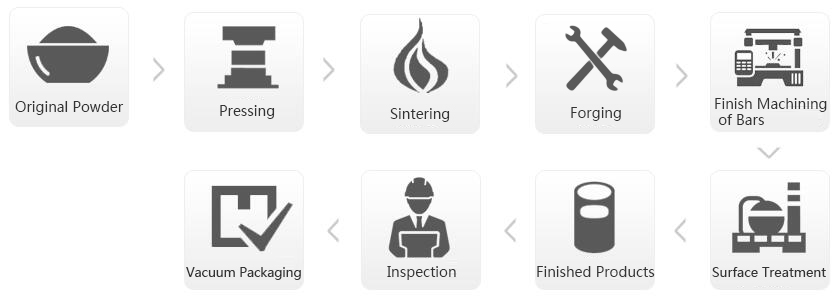

Fasteners of our company are formed by deep-processing high-density large-deformation bars and plates. Without the phenomena of thread falling and corrosion, molybdenum screw rods and molybdenum nuts have good high-temperature resistance, and can achieve firm connection at high temperature. Meanwhile, our company carries out special treatment on the surfaces of fasteners by mechanical polishing and electrolytic polishing processes, so that the products have uniform surface colors and luster as well as more attractive appearance on the basis of ensuring stable using performance of products. All the products passing the inspection are vacuum-packaged by plastic bags.

We have a large number of precision CNC lathes, machining centers, wire-electrode cutting devices and other facilities. We can manufacture screw rods with GB threads, inch threads and US system threads, inner hexagon, outer hexagon, straight slots, cross slots and so on according to customer requirements, and can also process products according to drawings required by customers.

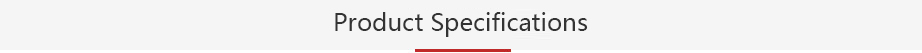

| Classification | Specifications |

| Screws | M3、M4、M5、M6、M8、M10、M16, etc. |

| Nuts | M3、M4、M5、M6、M8、M10、M16, etc. |

| Pins | Processing as required |

| Rivets | Ф1.2、Ф1.5、Ф1.8、Ф2.0、Ф2.5、Ф3 |

| Gaskets | Processing as required |

Product Applcation:

▲Bolts and nuts for sapphire crystal furnaces

▲Tungsten screws, molybdenum screws, tungsten nuts and molybdenum nuts for high-temperature vacuum furnaces or gas heat preserving furnaces

▲Fasteners for the monocrystalline silicon industry

▲Shielding screws for semiconductor and electronic industries

+8613526941255

+8613526941255

Message

Message